Slim rod is a stick-looking material used when pulling out polycrystalline silicon.

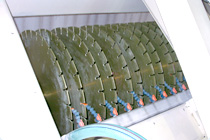

Multi-cut

Cut polycrystalline silicon into plural plates, and then cut each plate into multiple square sticks.

Multi-cutter

- Cut polycrystalline silicon and make square sticks by the multiple lines of the blades.

- To improve efficiency, the main shaft has multiple lines of blades for severing silicon into multiple sticks at once.

Chamfering

Chamfering of the slim rod.

Slim rod cutting

Cut slim rod into any length.

Slim rod cutter

- Cut multiple slim rods at once to any length.

- A single device covers both seed material and wading material, realizing auto-cutting in succession.

Various processing of slim rod

Drill the hole in a slim rod.

Wading drilling device

- Drilling equipment for materials mainly wading.

- Automatic drilling device for Silicon plate ( 8 ~ 10mm × 13 ~ 15mm × 200 ~ 260mm )

- Starts from the intake of material, via drill processing, finishes in sending out the completed products. The process is automated so that day and night operation is available.

Chamfering and tapered processing of slim rod.

Slim Rod tip rounding (tapered processing) machine

- Automatic processing of seed material chamfering and tapered processing.

- A single unit covers seed material chamfering and tapered processing in succession.

- Movement of the material among the process is fully automated by transfer equipment.

- Improves yield by saving labor and preventing damages to the product during the transfer process.

![]()

![]()

![]()

![]()

![]()

![]()

![]()