In contrast to the homogenous atom framework of monocrystalline silicon, polycrystalline silicon is composed of a number of smaller crystals or crystallites randomly associated.

Generation of metal silica

Quarry the silica from the mountains, and then restore it to a silicon metal with carbon.

Polycrystalline silicon deposition

Produce Trichlorosilane from silicon metal, and increase the purity of Trichlorosilane through a distilling and purifying process. After high temperature reduction with hydrogen, deposit high-purity polycrystalline silicon (polysilicon).

Polycrystalline silicon generation

Melt polysilicon in a furnace, then solidify by cooling it in a crucible.

Polycrystalline silicon wafer manufacturing

1.Processing to the shape of a prism

Severing an ingot to multiple the prisms.

Bandsaw

- High precision cutting with less kerf loss.

- Capable of top & tail cutting of the next process.

2. TopTail & cutting

Cut the top and tail, and remove the surface layer.

Simple cutter

- Fast cutting of top and tail

- Cost performance is better than a bandsaw

3. Risk aversion treatment

To avoid any risk in the slicing process of wafer manufacturing, the end face of the quadrangular prism is grinded to 90 degrees.

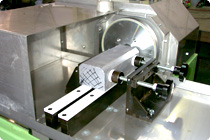

Face grinding equipment

- Grind the end face of a silicon block in high precision for solar use.

- Revise the end squareness of a silicon ingot to an accurate angle through grinding, to avoid the wire from breaking in the slicing process which occurs due to inaccurate end squareness.

4. Treatment of wafer yield enhancement

To improve the yield of the wafer, the damaged layers of the R-surface and the flat plane are removed through grinding and polishing.

Multi-axis grinding and polishing equipment

- With a multi-axis head, the device grinds and polishes the plane, the R-surface and C-surface.

- By using a work-stocker, the machine runs 24 hours a day from injection, via cutting and polishing, to the ejection of the work.

> Check details

5. Wafer manufacturing

Slice with wire-saw and manufacture wafer.

Various processing of polycrystalline silicon

Polycrystalline silicon ingot cutting machine

- Cutting polycrystalline silicon ingots in order to remove impurities effectively in the later process of polycrystalline silicon manufacturing.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()